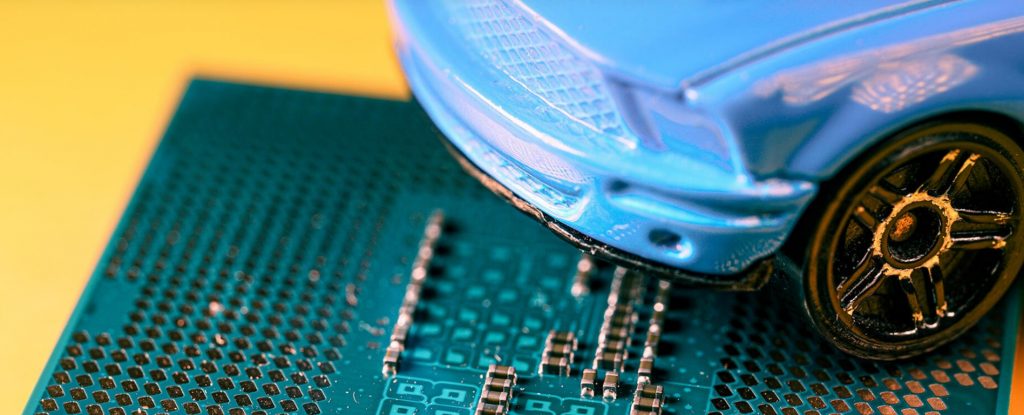

According to MIT Sloan, and our own experience, the auto industry was hamstrung by the global microchip shortage in 2021, resulting in losing more than $200 billion. Eleven million fewer vehicles were produced; manufacturing plants idled. Ford suspended operation at some plants to focus efforts on truck assembly, where the margins are better.

No single cause accounts for the microchip shortage. COVID-19 has had an outsized effect on the problem, as factories and ports closed while millions of people worldwide established home offices. But other contributors include labor shortfalls, lack of raw materials, trade tensions, and the growth of 5G electronics, which require more chips than previous generations of devices.

How are they responding?

Most immediately, companies are taking whatever microchips they can get and then building more adaptive manufacturing processes to deal with the obstacles that arise from this indiscriminate approach.

Companies are also looking into ways in which rewriting software might patch some of the shortage; perhaps code can be rewritten in such a way that a single chip can do more work than it formerly did.

In other words, they are getting creative, which is what Unionwear had to do at the outset of the pandemic as well.

Dad Caps

Dad Caps

Five Panel Hats

Five Panel Hats

Mesh Back Hats

Mesh Back Hats

In Stock Blanks

In Stock Blanks

Snapback Hats

Snapback Hats

Stretchfit Hats

Stretchfit Hats

Duffel Bags

Duffel Bags

Backpacks

Backpacks

Tote Bags

Tote Bags

Computer Bags

Computer Bags

Sling Messenger Bags

Sling Messenger Bags

Cooler Bags

Cooler Bags

Cuff Hats

Cuff Hats

Beanies

Beanies

Scarves

Scarves

Zipper Folders

Zipper Folders

Stitched Folders

Stitched Folders

Accordion Folders

Accordion Folders

Ring Binders

Ring Binders

Letter Folders

Letter Folders

Clipboards

Clipboards

Union Made In USA

Union Made In USA